business-services

July 22,2025 • 3 min read

Barcode Stickers: A Comprehensive Guide

Barcode stickers are an essential component of modern business operations, offering an efficient and accurate way to track products, manage inventory, streamline shipping processes, and improve overall operational efficiency. From retail and warehousing to healthcare and manufacturing, barcode sticker are used across virtually every industry due to their versatility and reliability.

What is a Barcode Sticker?

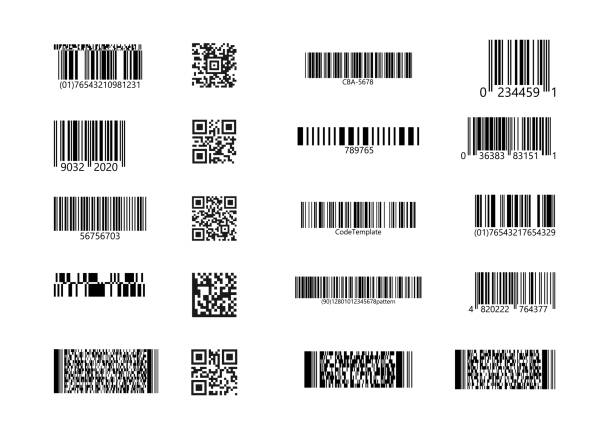

A barcode sticker is a label that contains a printed barcode symbol—usually a series of parallel black lines and spaces of varying widths, or a 2D matrix pattern. This barcode holds information that can be scanned and interpreted by barcode readers or smartphone apps. The sticker is usually made of paper, polyester, polypropylene, or vinyl, with an adhesive backing that allows it to be affixed to a wide range of surfaces.

Types of Barcodes Used on Stickers

There are two main categories of barcodes commonly used on barcode stickers:

1. 1D Barcodes (Linear Barcodes)

These are the traditional black-and-white bars most people are familiar with. Examples include:

-

UPC (Universal Product Code) – Common in retail.

-

EAN (European Article Number) – Used globally for product identification.

-

Code 39 and Code 128 – Common in inventory and asset tracking.

2. 2D Barcodes

These store data in both vertical and horizontal directions and can hold significantly more information.

-

QR Codes (Quick Response) – Used for marketing, payments, and contactless systems.

-

Data Matrix – Ideal for small items and commonly used in electronics and pharmaceuticals.

-

PDF417 – Used in transport, logistics, and even ID cards.

Materials Used for Barcode Stickers

The durability and functionality of a barcode sticker largely depend on its material. Some of the common materials include:

-

Paper: Cost-effective and used for temporary or indoor applications.

-

Polyester: Durable, resistant to chemicals, and suitable for harsh environments.

-

Vinyl: Flexible and ideal for curved or irregular surfaces.

-

Polypropylene: Resistant to water and wear; used in packaging and outdoor labeling.

Adhesive Types

The effectiveness of a barcode sticker is also influenced by the adhesive used:

-

Permanent Adhesive: Ensures the label stays on for the lifetime of the product.

-

Removable Adhesive: Allows the sticker to be peeled off without leaving residue.

-

High-Temperature Adhesive: Designed for environments with extreme heat, such as automotive or industrial settings.

-

Cryogenic Adhesive: Used in laboratories where labels must withstand freezing temperatures.

Applications of Barcode Stickers

Barcode stickers serve numerous purposes in various industries:

1. Retail

-

Price tagging

-

Inventory management

-

Sales tracking

-

Anti-theft tagging

2. Healthcare

-

Patient identification

-

Medication tracking

-

Laboratory sample labeling

3. Logistics and Warehousing

-

Shipment tracking

-

Package sorting

-

Shelf labeling

4. Manufacturing

-

Asset management

-

Quality control

-

Production monitoring

5. Education and Libraries

-

Book cataloging

-

Student and staff ID tags

-

Equipment tracking

Benefits of Barcode Stickers

-

Efficiency: Speeds up data entry and reduces human error.

-

Accuracy: Ensures precise tracking and identification of items.

-

Cost-Effective: Inexpensive to produce and implement.

-

Versatility: Can be customized in size, shape, and design.

-

Scalability: Works across a wide range of applications from small businesses to large enterprises.

All services030 Details

User Profile

- Full name

- All services030

- Email address

- allservices030@gmail.com

- Join Date

- 2025-07-17

- State

- City

- Pincode

- Address

- Follow us on Facebook

- Follow us on Twitter

- Website Name

- Bio